Fisher heatbed upgrade

Summary

Upgrade your Fisher Delta 3D printer to use a heated print surface. This upgrade will enable your machine to 3D print using a broad range of thermoplastic materials, including ABS, HIPS, PETG among others.

Requirements

Heatbed upgrade (Heatbed kit, 120W power supply, Kapton tape)

Build instructions

Assembling the heatbed

You will need the following parts:

Fitting instructions

| Exploded view of heatbed assembly. |  |

| Insert the coutersunk screws, then fit the bMDF insulator and six M3 washers. |  |

| Drop the reflective shield onto the assembly as shown, ensuring the reflective side faces the PCB. |  |

| Fit the base plate and secure with six M3 nuts. |  |

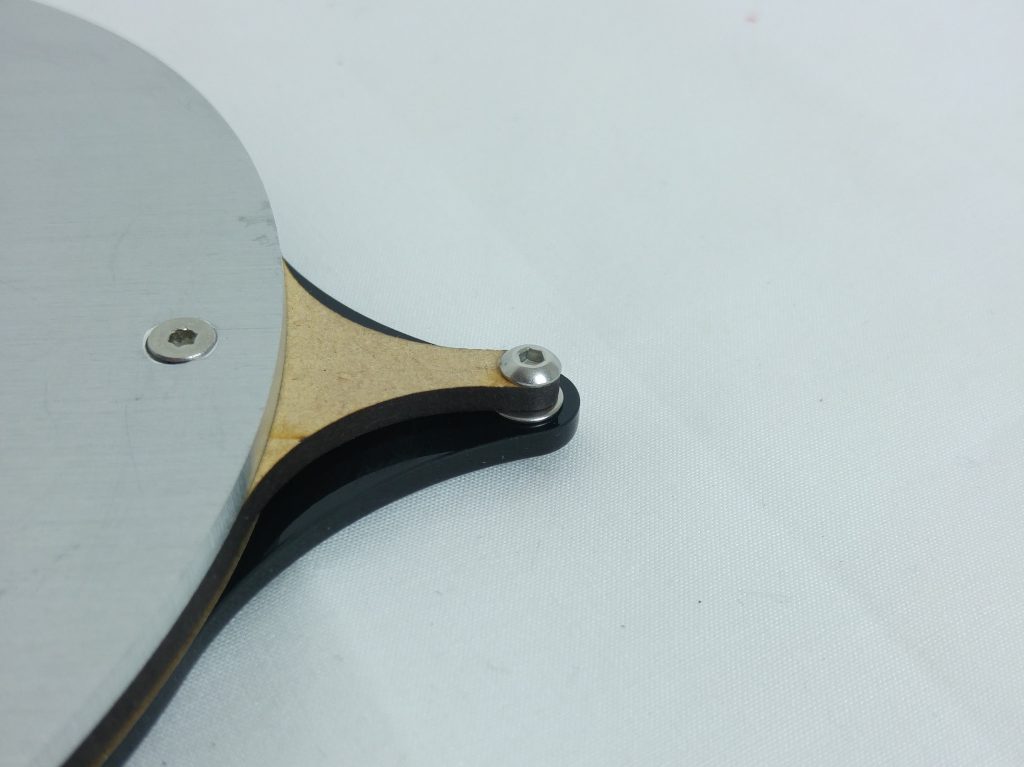

| Place a washer between the base plate and MDF insulator at each of the three remaining holes. Screw a button head screw into each hole. The threads should cut into the acrylic. |  |

| Remove the old bed and fit a 2mm spacer under each of the bed springs. |  |

| Apply Kapton tape to the Aluminium bed, then fit the heatbed assembly and thread the wires through the machine’s base plate. |  |

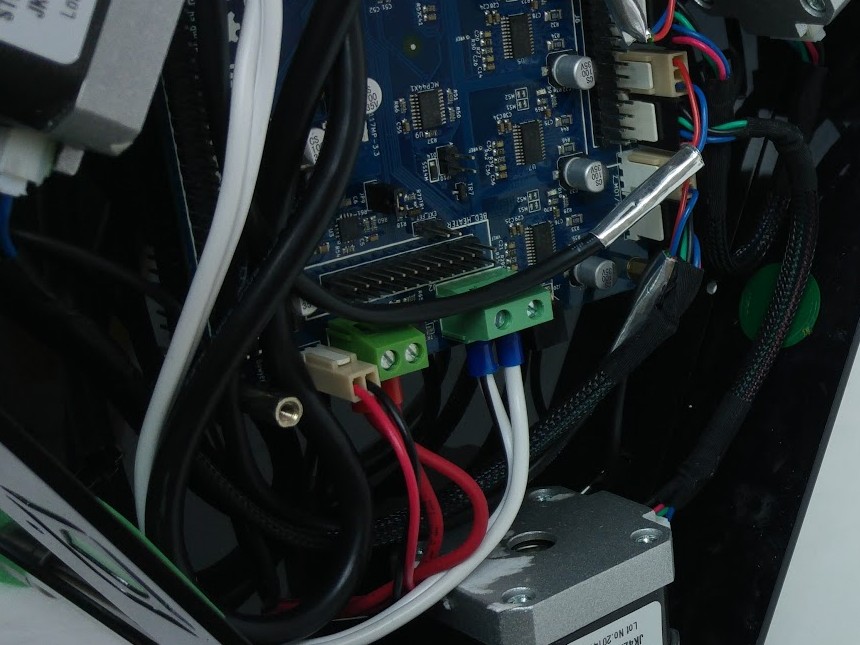

| Fit the 2-way housing onto the thermistor wires, then connect to the Duet as shown. The orientation of connections is not important. |  |

Commissioning the heatbed

You will need to make a few changes to your machine’s configuration file, config.g, in order to use your new heatbed. The latest sd-image files can be found in our github repository here. A sample config file for use with a heatbed is available here. If you have made changes to your config.g file from the original, it is best to compare your version with config.heatbed.g and edit you config file. The config.heatbed.g file can be used, but will need to be renamed to config.g to be effective.

The power available for the heaters (hot end and bed) is set to safe limits by the S parameter in command M301. These can be adjusted depending on the power available from your power supply.

Printing tips

The heatbed can reach in excess of 100C, useful for printing with materials such as ABS and HIPS, however this will take a few minutes so be patient.

Kapton is a very reliable print surface for use on a heatbed.

It is recommended to run the bed calibration routine at the start of a print, once the bed and hot end have reached printing temperature. This can be achieved by adding the following lines to your Start G-Code in under the Slic3r Printer Settings tab:

M83 T0 M116 G32