New home

Welcome to eMAKER’s new online home. Having setup and run eMAKERshop for many years, the time has come to focus our efforts on our own products and new developments.

History

From our humble beginnings in a Milton Keynes garden shed five years ago, our mission hasn’t changed since successfully launching the first 3D printer crowd funding campaign.

That mission is to offer people access to great technology at a reasonable price. At the time of our Indiegogo campaign, access to 3D printers was limited. The likes of Makerbot and Ultimaker were still getting going with their first generation products, and big names such as 3D systems and XYZ had not even entered the consumer 3D printing marketplace.

There were a limited number of RepRap designs published, but full kits were very hard to find. So the eMAKER Huxley was born to offer a complete 3D printer kit, for a reasonable price. The design was an evolution of the original Huxley design, which itself was based on the original Sells Mendel design with all it’s bearings, but simplified by taking much inspiration from Josef Prusa’s first Mendel iteration. The eMAKER Huxley was, and in some cases still is, a very capable little 3D printer, with a heated bed and our all metal hot end the print quality was still better than many printers on the market today.

Of course the consumer 3D printing market has grown up a lot in the last five years, and some big names have entered then left in that time, including RepRapPro and 3D Systems who no longer offer machines aimed at the home user. The early hype, proclaiming 3D printers would bring Star Trek like replication to the living room has thankfully died down, and the technology has found it’s footing as a key prototyping and even small batch manufacturing tool.

Products

RepRap 3D printer kits will always have a place in the market, perhaps in the same way kit cars do despite the plethora of mass produced cars, as there are many benefits to building your own 3D printer. Such a market is likely to remain a minority as the mass produced injection moulded machines and accompanying software continue to improve.

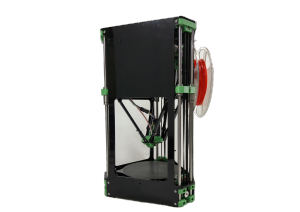

It is for the above reasons that eMAKER will continue to offer a 3D printing solution in the form of the excellent Fisher Delta, but on a smaller scale than we tried to achieve through RepRapPro. Although currently the main offering of this site, 3D printers will be just one of many tools and projects we hope to bring you as this site grows with content.

Newsletter

So if you’d like to get into 3D printing, we recommend starting with the Fisher Delta. If you already have a 3D printer, or are simply interested in what we plan to offer, please feel free to sign up to our mailing list so we can keep you up to date with our latest developments.

Please also feel free to leave your comments below, or email us at info@emaker.io

Neal Atkinson

Nice new site although I used to like browsing all

As to home build you should invest design time into (especially the width control) in home build filament extruder (laymen), home builders make their machines with your parts. They guna want filament.

Never understood the omrod

Best regards and thanks for the parts

natko

jeanmarc

Hello natko,

Thank you for your kind words. We have considered developing a desktop filament extruder, but are focusing on other products at the moment. Desktop filament extruders have been around for a few years now, kicking off with the Filabot device which was successfully crowd funded on Kickstarter in 2012, and the Lyman extruder published on Thingiverse in 2013. There is a good summary here.

Phil Balaam

We use 3D printing to print obsolete plastic parts for vintage HiFi equipment!

We’ve recently bought a Fisher delta printer from eMaker to compliment (and hopefully improve) on the results from our first generation Reprap Huxley, and also learn something about Delta printers and their advantages and disadvantages.

First task was to prove that eMaker was still alive given that most of the posts were at least 6 months old.

A quick e-mail got an equally quick response so we ordered a kit which arrived in good order in a couple of days.

Build instructions were (as with all reprap printers) excellent and easy to follow so anyone with any common sense and mechanical undestanding should be able to build one of these kits.

We had a few issues getting it to print properly (all our fault 🙂 but a few e-mails back and forth to eMaker helped us to identify the issues and solve them quickly (and learn something in the process).

We,ve now started to upgrade the Huxley to the newer Duet controller board (also bought from eMaker) as the web interface on the Duet controller means that any computer with a decent web browser can upload files to the printer and print them.

Some commercial 3D printers seems to be following the pattern of computer printers in selling the printers at a loss and then charging a small fortune for the filament (and making sure you can only use their filament by using special filament containers or ID chips) so anyone who wants a 3D printer which will last more than a year or so should seriously consider an open source printer.

Thanks to Jean-Marc at eMaker for helping out and proving that good customer service still exists. You just need to put some more posts on the blog to show that you’re still going!

Almost forgot! – print quality of the Fisher is extremely good compared to the Huxley and about as good as I’ve ever seen from an extrusion printer. Well reccomended (especially for schools and people who want to learn how they work!)

Thanks to all in the Reprap community for all the hard and selfless work in proving that a sucssesful product doesnt have to involve secrecy and greed and actually might be a positive selling feature!. keep up the good work

Phil (MD Nytech audio)